What is it like to work at the Dinolift factory in Loimaa, southwest Finland? Supervisor Matti Kyläsorri gives us a glimpse into a typical day at the welding and machining units.

The long operating life of DINOs is based on our commitment to in-house welding and machining. Our skilled welders are dedicated to building machines that can handle even the most extreme work conditions and varying environments. Matti Kyläsorri has worked with Dinolift as a supervisor at the welding and machining units for the past year. Let’s look at his typical day at the factory.

5:30 AM

We’re in the process of moving from the old Kurittula premises to the Raikkola main factory. When the move is done, all operations will be under the same roof. But for now, my day starts at Kurittula. I check all the working hours from the previous day and after that, I’ll do my rounds at the stations and discuss the day’s work with the team leaders.

7:00 AM

The ongoing traffic between the old and new factories requires attention. Even though the drivers are proactive, I still must oversee deliveries between them to ensure everything goes smoothly. I get calls from different units when they need something from the other building and stay connected with our subcontractors who provide us with machine parts. I keep track of the different materials in stock and make sure that we don’t run out of anything.

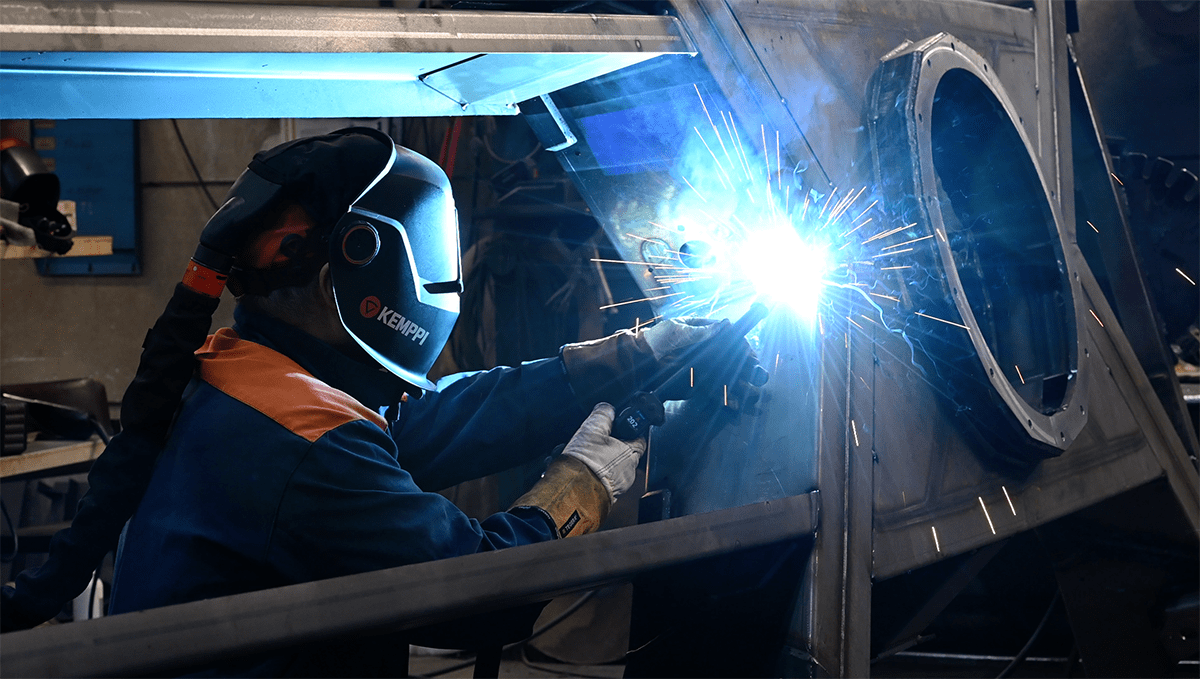

Supervisor Matti Kyläsorri thinks moving to the new factory will significantly improve the workflow for the welders and the entire production. Credit: Dinolift

Supervisor Matti Kyläsorri thinks moving to the new factory will significantly improve the workflow for the welders and the entire production. Credit: Dinolift

8:45 AM

During our daily morning meeting at Raikkola, the production manager, other supervisors and representatives from acquisition give an update on current tasks. We also go through work that’s coming up over the next two weeks. If there are any potential issues in component or material supply, I’ll inform the team and we’ll plan accordingly. It’s a useful meeting that provides a complete picture of what’s happening in different production areas.

9:00 AM

Some welders have already moved to the new factory, so I’ll do my rounds there as well. I check with the team leaders to see how projects are progressing and ensure that they have all the parts they need for production.

I’m looking forward to the move since it will save us time and make operations more efficient. Besides state-of-the-art equipment, the new factory has a dedicated welding building, improved ventilation and better lighting to make work more comfortable for us.

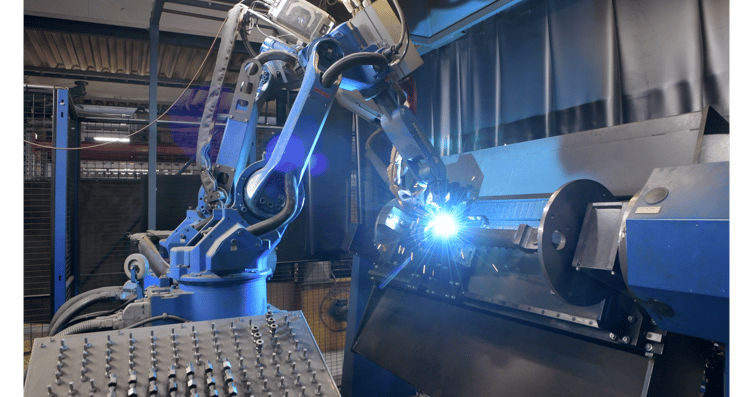

At the new factory, there are welding robots and a brand-new laser welding station. Image credit: Dinolift

At the new factory, there are welding robots and a brand-new laser welding station. Image credit: Dinolift

11:00 AM

My tasks focus on managing the machine parts and component supply. As it has been with most industries, we have had issues over the past couple of years—personally, I don’t even know how things work in ‘normal’ situations! Right now, we’re working around the supply issues the best we can. For example, if we know there’s a component that we can’t get on time, we need to focus on something else until the issue is resolved.

12:00 PM

During midday, I get lunch from the main factory. One of the highlights of the day is sitting down with other supervisors to discuss everything and anything under the sun. It’s a welcome break from the day’s work. And the atmosphere at the factory is very good.

1:00 PM

During the afternoon, I make another round at the main factory before ending my workday. Besides the welding units, I’m also responsible for the machining lines. We recently received new parts for the welding robots, which will be installed in the upcoming weeks. Investments like these that Dinolift is making give me a sense that the work matters and that we’re growing as a company. It’s exciting to see how things will evolve.

%20(1).png?width=363&name=MicrosoftTeams-image%20(3)%20(1).png)